Case Packer MF CUBE Machine - Top Loading

The Case Packer MF CUBE is a high-tech machine able to form, fill and close American-type boxes (RSC cases). Any type of product can be placed inside the box.

UP TO 12 BOXES/MIN SPEED

HIGHLIGHT FOR STANDARD CARDBOARD BOXES

The Case Packer MF CUBE is a secondary packaging system for top loading of bags, doypacks, bottles and every type of containers into American cases (also known as RSC cases).

How MF CUBE Case Packer works in short:

Three basic steps:

- Forming and sealing the bottom of the case

- Picking up and leave the product into the case, using a special Pick&Place system

- Sealing the bottom of the case

Case type: American case (RSC).

Your product: Bags, doypacks, bundles, bottles and every type of containers can be placed inside the case.

What makes it special:

- Modular system: possibility to choose the stations needed and to combine them freely

- Entirely made of AISI 304 stainless steel

- Type of Sealing: hot melt glue, adhesive tape or combination of both

- Flexibility: possibility of adding robotic stations or sealing systems at a later time

- Pneumatic Pick and Place system: flexible, adaptable to any production needs

- Product positioning inside the box according to shape and rigidity needed

Let’s know more about MF CUBE Case packer!

Modular Structure: complete customization and the inclusion of various components that suit the production requirements the best.

High hygienic standards: structure entirely made of stainless steel AISI 304. Ideal for food products.

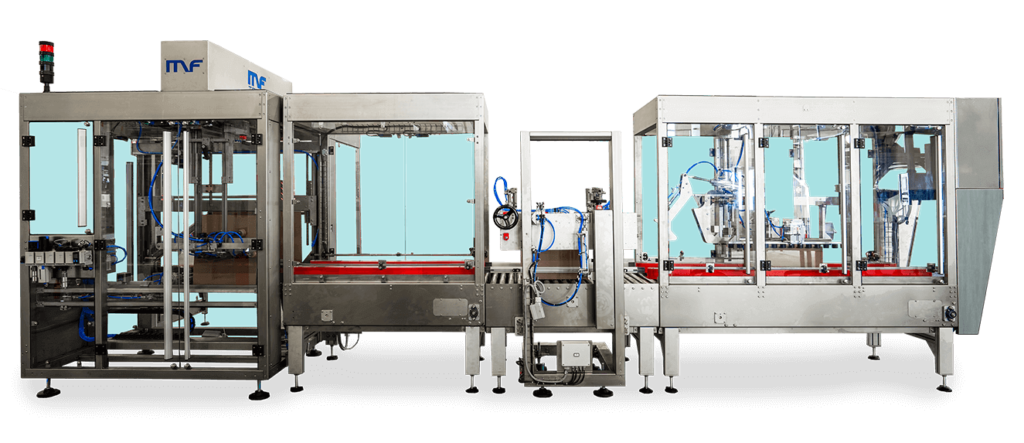

The MF CUBE Case Packer Machine is a complete robotic packing solution, composed of 5 units:

- The empty boxes dispenser. Available in automatic or gravity-based version.

- Box erector to form the box

- The loading roller conveyor

- Top loading Pick and Place System

- Box closing and sealing by hot melt glue, adhesive tape or combination of both

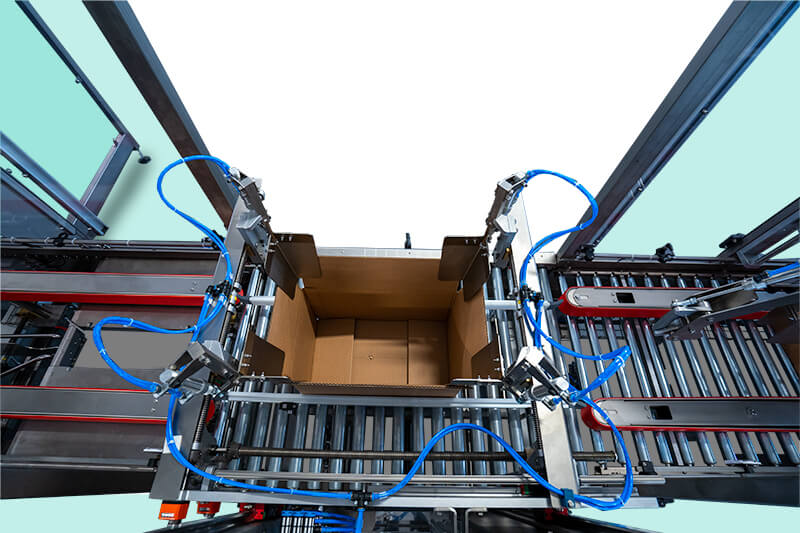

The closed cardboard is picked up from the dispenser and opened by means of suction cups mounted on a mechanical arm.

The cardboard is held by suction cups even during the folding of the lower, front and rear flaps to get the maximum precision.

On the roller conveyor the box is centered, closed on the bottom and dragged towards the sealing unit to have a perfect shape retention. The sealing can be done with adhesive tape, hot melt or by both sealing methods.

The insertion of the bags into the case can be managed automatically (by Pick and Place system) or manually.

The flaps opening system can be either automatic or semi-automatic. This system guarantees the perfect centering of the box at the time of insertion by Pick and Place.

After the filling station, the American case (RSC) is transported to the upper closing station.

The sealing can take place by means of tape, hot melt or with both methods.

In the following photos you can see MF CUBE Case Packer Machine, complete with automatic empty box dispenser, Pick and Place system and flaps opening device.

CAPACITY:

Up to 12 boxes/min Speed

Features

- Possibility of handling boxes of various dimensions

- Intuitive, simple and fast adjustments and use

- Empty boxes dispenser. Available in automatic or gravity-based version

- Suction cup withdrawal unit mounted on a pneumatically. driven swing arm.

- Machine on height-adjustable feet.

- EEC compliant material.

Options

- Remote assistance

- Manufactured in stainless steel

- Automatic format change

- Horizontal motorised storage

- Box closure using adhesive tape or hot glue