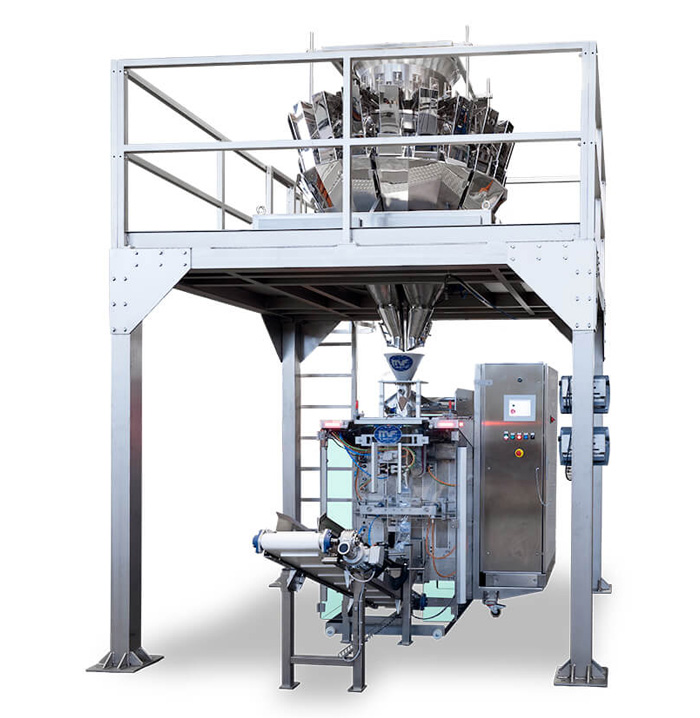

MF 50 SPEEDY Vertical Packaging Machine

High speed continuous vertical packaging machine for small formats. Ideal for high production.

The MF 50 SPEEDY continuous vertical packaging machine is specifically designed for those seeking high output for small formats.

This machine can handle bags ranging from 50 g to 1 kg, achieving an impressive production speed of 105 bags per minute.

Its key differentiating features are:

- Continuous ‘up-down’ movement of the sealing bars, powered by brushless motors.

- An innovative plastic film traction system controlled by two independent brushless servomotors.

- Continuous movement of the sealing bars, which allows much higher output compared to other machines in its class.

Compact and suitable for limited spaces, this machine is fast, flexible, and easy to maintain.

It can be equipped with different dosing systems depending on the product being processed and the customer’s specific requirements.

The machine can handle a wide variety of products, with the most common being seeds, dried fruit, rice, pasta, and pet food.

Bags are formed from flat reels made of multilayer materials (AL/PE, paper/PE, PA/PE, or PP/PE) to ensure that the continuous welding perfectly seals the materials.

The bags produced (with minimum dimensions of 40×50 mm and maximum dimensions of 190×400 mm) can be pillow-shaped, square-bottomed, four-sealed, gusseted, or doypack-style.

The built-in touch screen panel allows the operator to manage the entire production cycle.

Constructed entirely from stainless steel, the machine is fully designed, manufactured, and tested in our production centre.

Thanks to its versatility, it can also easily integrate with bundling or boxing systems.

ROI CALCULATORCAPACITY:

The machine can handle bags from 50 g to 1 kg.

BAG TYPE:

Pillow, similar to doypack, square bottom, with 4-seals, with clinched edges, with gusset

Features

- High production capacity thanks to the particular drive system, the continuous movement of the sealing bars, the choice of dedicated electronics managed by the PLC.

- Brushless motors that guide all machine movements

- Electronic management system able to constantly monitor the entire operating cycle

- Easy plant cleaning and dosing elements can be inspected completely.

- Flexibility of formats: quick release of the forming tube makes it possible to pass from one format to another very easily and quickly.

- Variety of formats: allows a wide range of formats to be made, which can meet the needs of medium and large industrial realities.

- Touch-screen operator panel

- Self-diagnosis system for anomalies and verification via display.

Options

- Pneumatic device for the creation of lateral gussets

- Modified Atmosphere Device

- Marker

- Printer

- Device for the removal of static electricity

- Device for the clinched edges

- 4-Sealing Device

- Handle Creation Device

- Zip Applicator

- Check-weigher with ejector

- Annular metal detector

- Remote assistance

- Product conveyor and loading system