ROTOTECH 3000

Rotating Arm Stretch Wrapping Machine

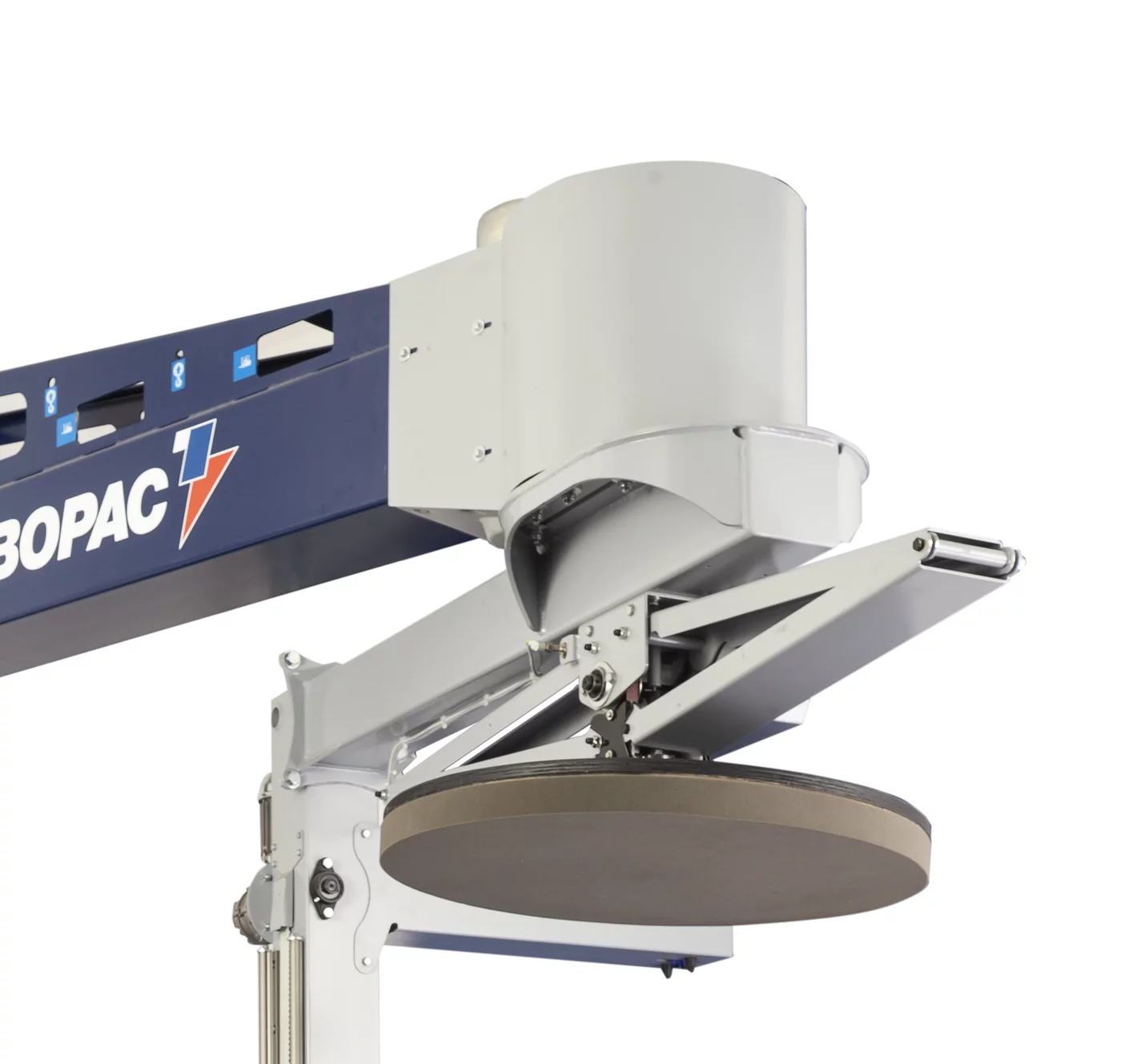

This is the ideal solution for automatically wrapping pallets with loads that are unstable or lightweight. This clever technology allows the pallet to stay stationary while the rotating arm applies the load containment wrap.

Easy to use thanks to large format touchscreens, this wrapper uses CUBE software to apply custom wrap configurations to challenging pallet loads. 85mm low-profile to 750mm high pallet conveying systems are available for greenfield projects or integration into existing lines.

DOWNLOAD DATASHEET ROI CALCULATORFeatures

- Automatic film clamping and cutting

- Working line height from 85mm to 750mm

- Variable pre-stretch up to 400%

- Easy to use 7″ touch screen control panel with cube technology

- Perfect for unstable A/O irregular pallets

- Ideal for logistics

- Max load weight 1500kg

- Max product dimensions 1650 x 1200mm

- Max load height 2000 standard

- Adjustable rotating arm depending by the pallet

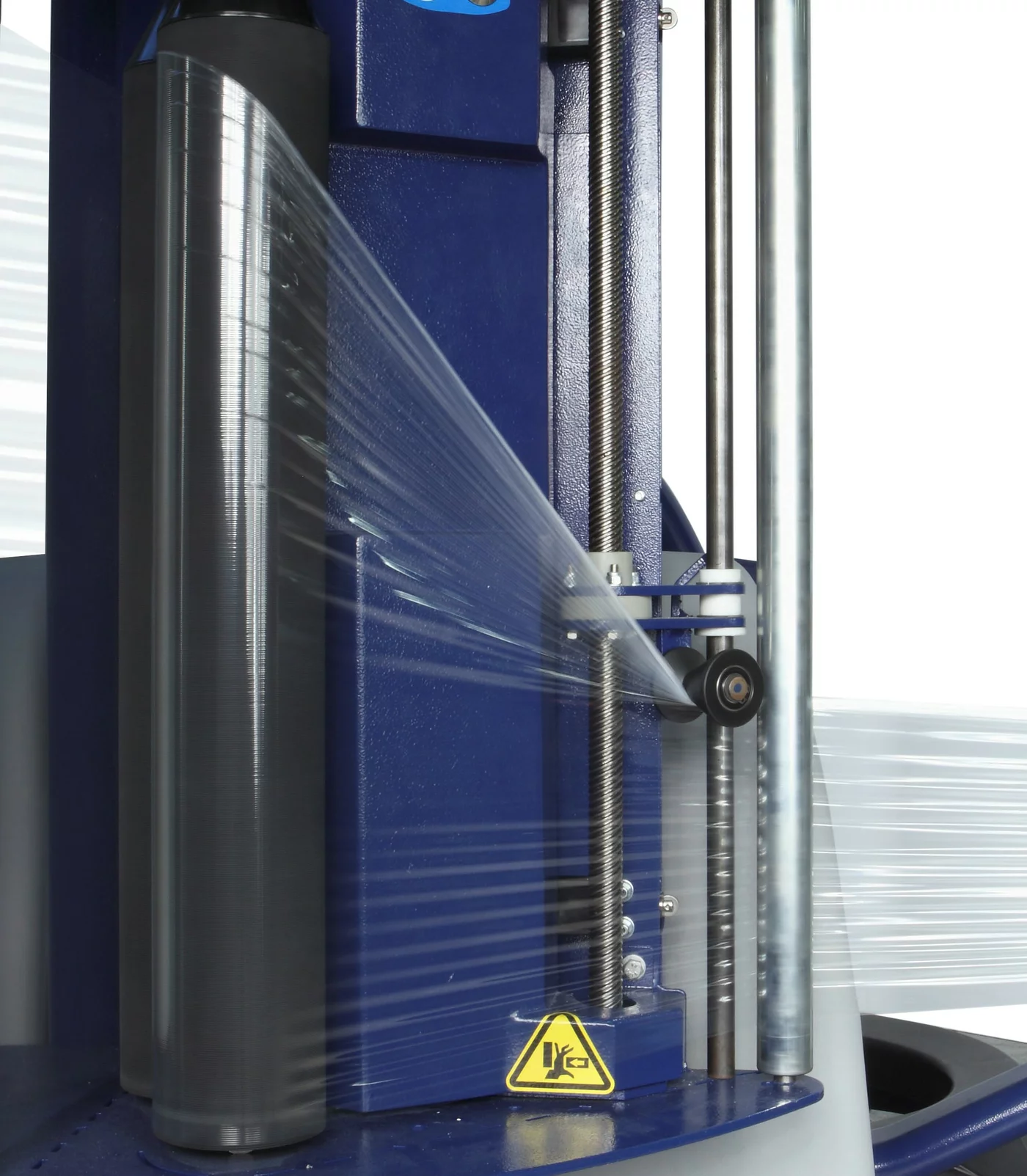

- Film Carriage – Film carriage with electromagnetic powder brake on return roller, stretch tension adjustable from control panel

- Film roping device for applying additional containment support to targeted areas on load

- R-Connect Wi-Fi connection

Options

- PGS Carriage – Pre-stretch system is fixed at 250%. “Stretch Control” control activates the electromagnetic clutch positioned on the first roller

- PVS Carriage -Powered stretch system controlled by two independent motors. Stretch ratio adjustable from panel board from 150% up to 400%\

- Max load height extensions 2400/2750mm

- Top presser plate for additional load stabilization during wrap cycle

- Top sheet application

- Pallet conveying, dispensing, integration, control