Vacuum Tube Lifters JumboSprint

For compact workpieces weighing up to 300 kg

The JumboSprint is equipped with a bow-shaped operator handle which extends all the way around the unit. This allows the user to optimally position it on compact goods such as bags or rubber bales. The load is raised by pulling up on the handle lever and lowered by pushing down.

Application

- Fast and frequent lifting and moving of compact workpieces up to 300 kg

- Handling of workpieces such as bags, barrels, buckets, jugs and rubber bales in internal logistics processes

- Ensures the flow of materials when loading or unloading of mixing machines

- Available in a stainless steel version for special ambient conditions, e.g. in food related areas

-

Modular System

-

Modular Elements

-

Technical Data

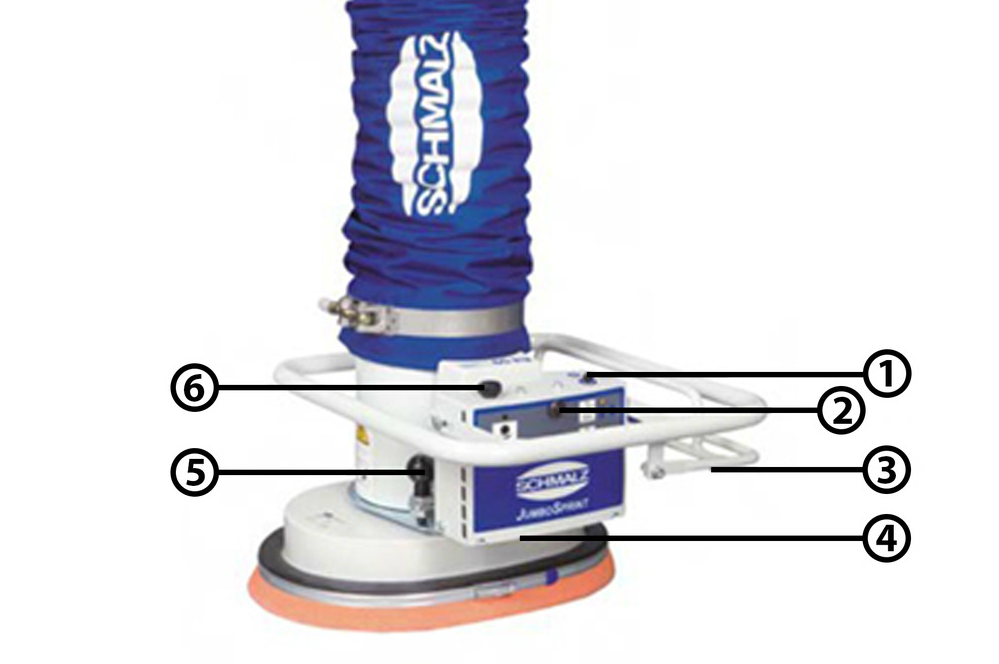

(1) Radio remote control SRC for vacuum generator (optional)

(2) Filter - changable without tools

(3) Bow-shaped Operator handle for Lifting, lowering and releasing the load

(4) Suspension height can be adjusted without the load attached

(5) Quick-change adapter for vacuum grippers (optional)

(6) Suspension height can be adjusted with a load attached

Versatility is key: Schmalz offers the right suction cups for virtually any application. With quick-change adapter the gripper can be changed quickly and easily.

For compact goods such as cardboard boxes, barrels, buckets, jugs and cabinets.

For pallets, narrow cardboard boxes, beams, square tubes and other elongated workpieces.

For barrels, buckets or stone slabs with rough surfaces.

For cardboard boxes, crates or sheets. The vacuum grippers can be continuously adjusted along the beam.

For pallets, sections or cut pieces where the vacuum gripper is not fully covered by the workpiece. The grippers can be continuously adjusted along the beam.

For large cardboard boxes, sheets and non-rigid pieces. The vacuum grippers can be continuously adjusted lengthwise and crossways.

For uneven workpieces such as foil trays or unstable cardboard boxes. The individual vacuum grippers optimally compensate for any unevenness.

For handling suction tight or porous paper, plastics and fabric bags.

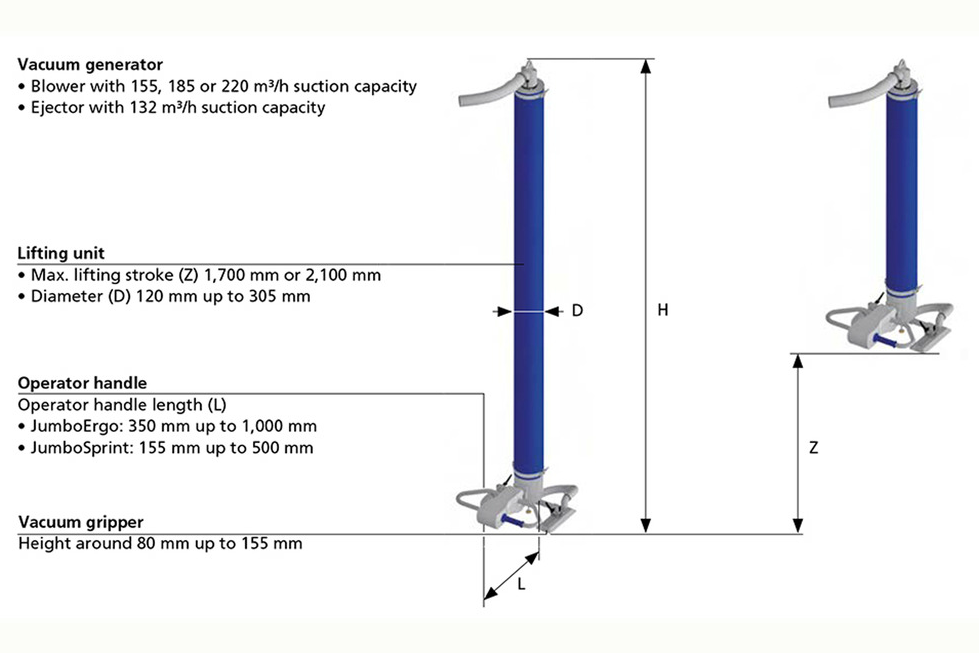

The vacuum tube lifters JumboErgo and JumboSprint can be configured specifically based on the requirements of each individual application due to their modular design. The technical data varies depending on the configuration and on the vacuum gripper chosen.

The following technical data are standard values.

| Type | Workpiece format* Min [mm] |

Workpiece format* Max [mm] |

Operator handle length L [mm] |

Max. lifting speed [m/min] |

Max. lifting stroke Z [mm] |

|---|---|---|---|---|---|

| JumboErgo | 300x200 | 4,000x2,000 | 350-1,000 | 60 | 1,700 |

| 300x200 | 4,000x2,000 | 350-1,000 | 60 | 2,100 | |

| JumboSprint | 300x200 | 3,100x1,000 | 155-500 | 60 | 1,700 |

| 300x200 | 3,100x1,000 | 155-500 | 60 | 2,100 |

A lift capacity of 140 kg and higher applies: lifting stroke Z +160 mm, height H +250 mm

*Depends on the vacuum gripper chosen

**Vacuum gripper not included (total height = H + height of the vacuum gripper)

| Jumbo Type | Max. lift capacity [kg] | Ø Lift tube |

|---|

| Horizontal | 90° swivel | D [mm] | |

|---|---|---|---|

| Ergo/Sprint 35 | 35 | - | 120 |

| Ergo/Sprint 45 | 45 | 30 | 140 |

| Ergo/Sprint 65 | 65 | 50 | 160 |

| Ergo/Sprint 85 | 85 | 70 | 178 |

| Ergo/Sprint 110 | 110 | 90 | 203 |

| Ergo/Sprint 140 | 140 | 120 | 230 |

| Ergo/Sprint 200 | 200 | - | 250 |

| Ergo/Sprint 300 | 300 | - | 305 |

Features

- All around operator handle for optimal transfer of force and guidance of the device

- Modular design and extensive gripper and accessories program for implementing individual requirements

- Increases employee motivation and minimizes work-related musculoskeletal disorders

- Optional rotation unit for continuously rotating and precisely positioning workpieces up to 200 kg

- Handling by only one person