System 2 Package:

APC-L10 Conventional Palletizer

Reduce labour, downtime and health and safety risks by eliminating manual handling of bagged product. This palletizer uses what’s called a conventional style palletizing system. These units are simple, robust, uncomplicated and very effective for applications up to 800 bags per hour.

Aurora’s conventional palletizer is very economical when it comes to valuable space. The compact construction means that it can easily replace most manual operations without requiring additional floor space. Its versatile design enables you to feed empty pallets to the palletizer from three sides, increasing options for positioning in your packing area.

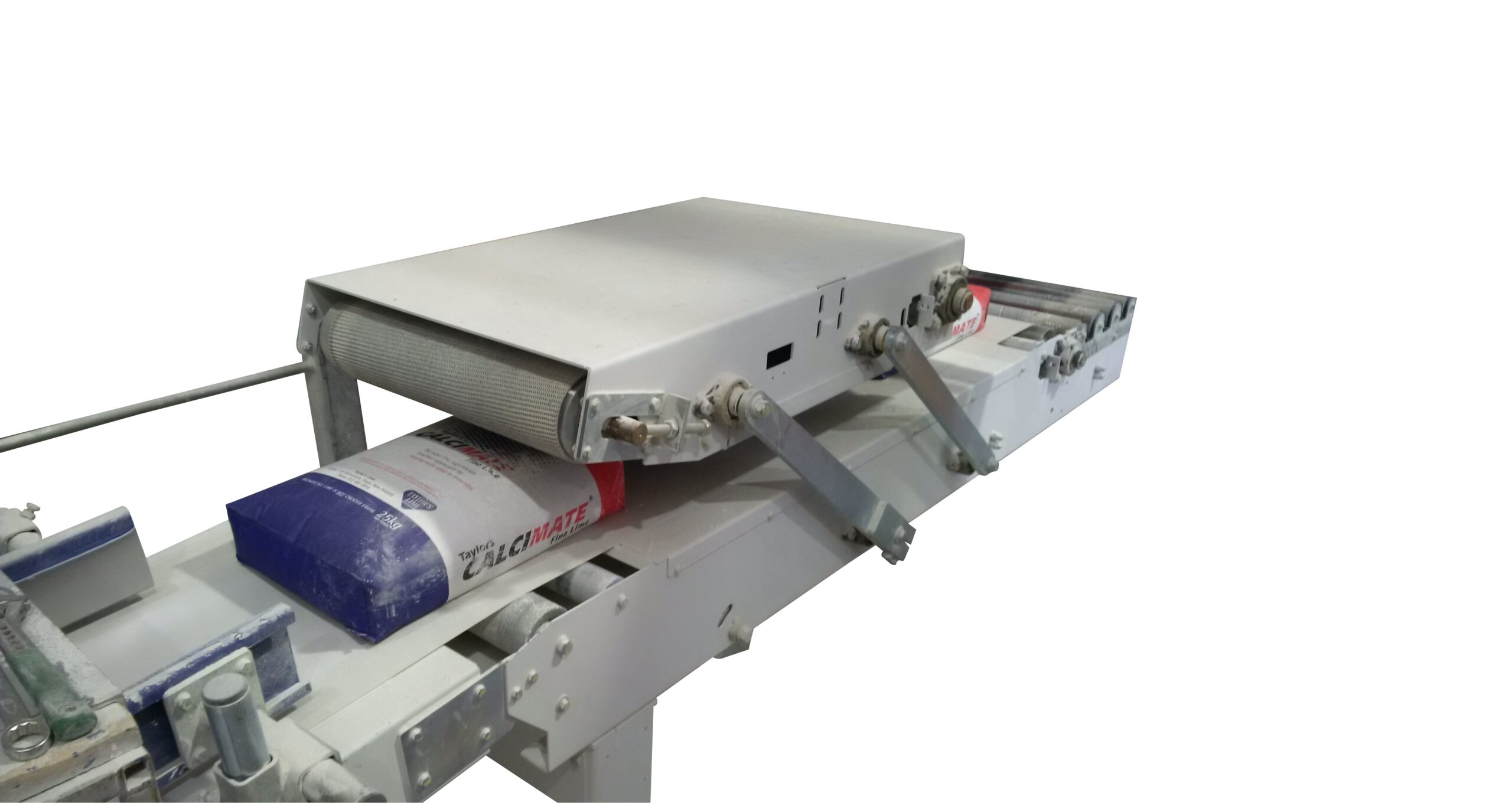

CB10 Continuous Band Heat Sealer

Intelligent and easy to operate. The CB10 provides an excellent high-integrity seal across a large range of bag materials and thicknesses.

Dual heating elements with independent controls allow a high degree of adjustment of the sealing configuration.

The CB10 is a reliable workhorse that gets the job done.

AFO-NT Net Weigh Bag Filling Scale

The AFO-NT net weigh scale is designed for packaging free-flowing, granular products into open mouth bags. The net weigh bucket continuously refills with product and is discharged by the operator’s signal.

The internal bulk and dribble flow gates are adjustable for use with a variety of products and the digital keypad provides easy set-up. Double bucket units provide a faster bagging rate and can be used for feeding automatic bagging systems.

Bag Kicking

Aurora Bag Kickers showcase great design allowing optimum kicking efficiencies in a compact footprint.

Using a pneumatic ram, the bag is kicked onto an adjoining conveyor or platform for further handling.

The kicker has been designed with safety in mind ensuring no pinch points or bag damage, providing a gentle and safer operation.

Bag Flattening

The AAF-B10 Belt Bag Flattener levels package contents over the full length of the bag prior to palletizing and wrapping to ensure that the pallets are stacked level and in a professional manner.

The bags are fed base first, onto a conveyor with an overhead powered belt or idler roller action. Simple and reliable for consistant pallet presentation.

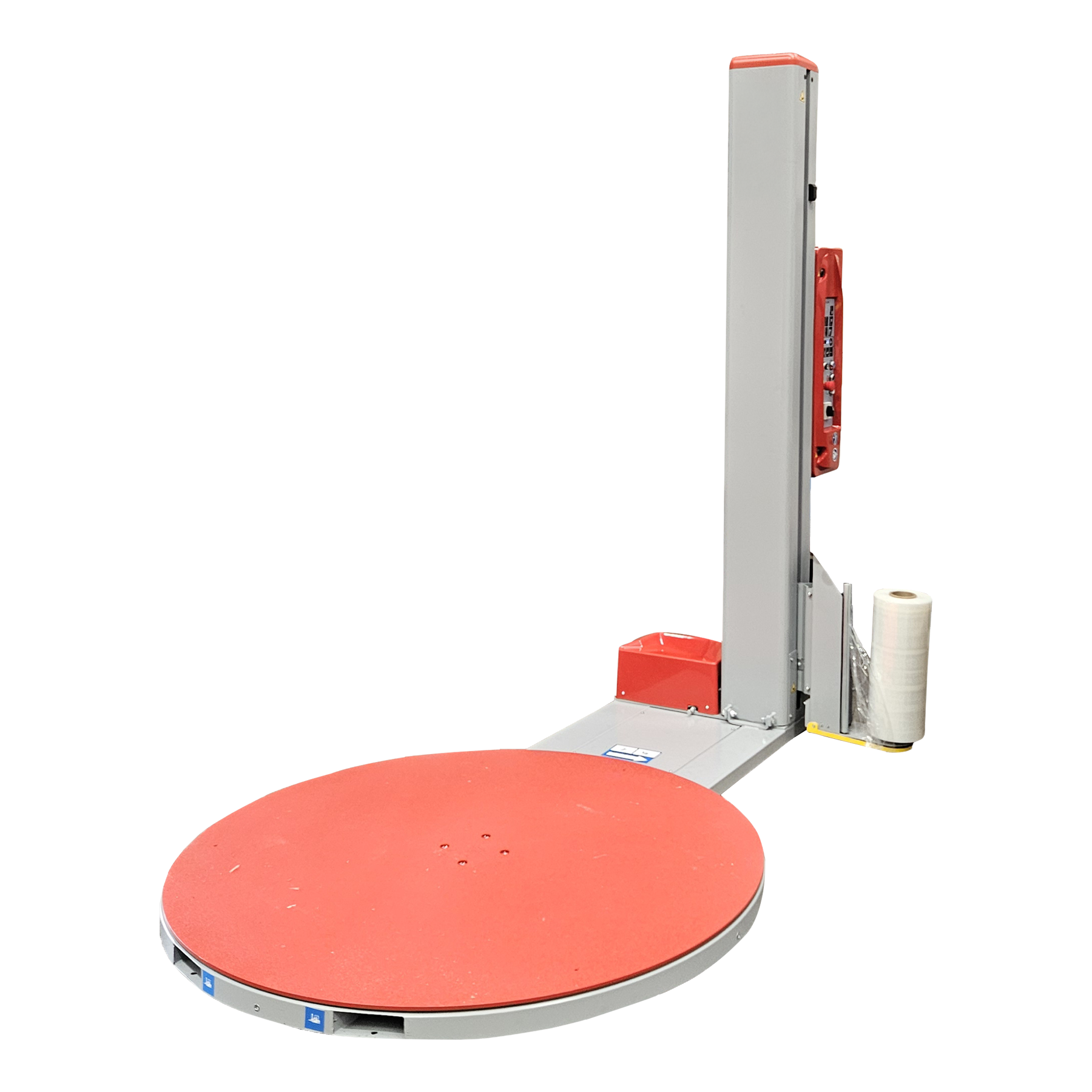

ECO Wrapper

Simple and reliable. This semi-automatic turntable is perfect for straightforward low-to-medium duty pallet wrapping.

The Eco has been designed by combining the best packaging technologies with innovative Italian engineering.

It’s ideal for most low-duty pallet wrapping applications. The adjustable acceleration and deceleration phases of the turntable ensure maximum safety when handling unstable loads. These features, along with the new carriage line and the “X3” control panel, make the Eco simple, sturdy, and reliable.

DOWNLOAD DATASHEET

ROI CALCULATOR