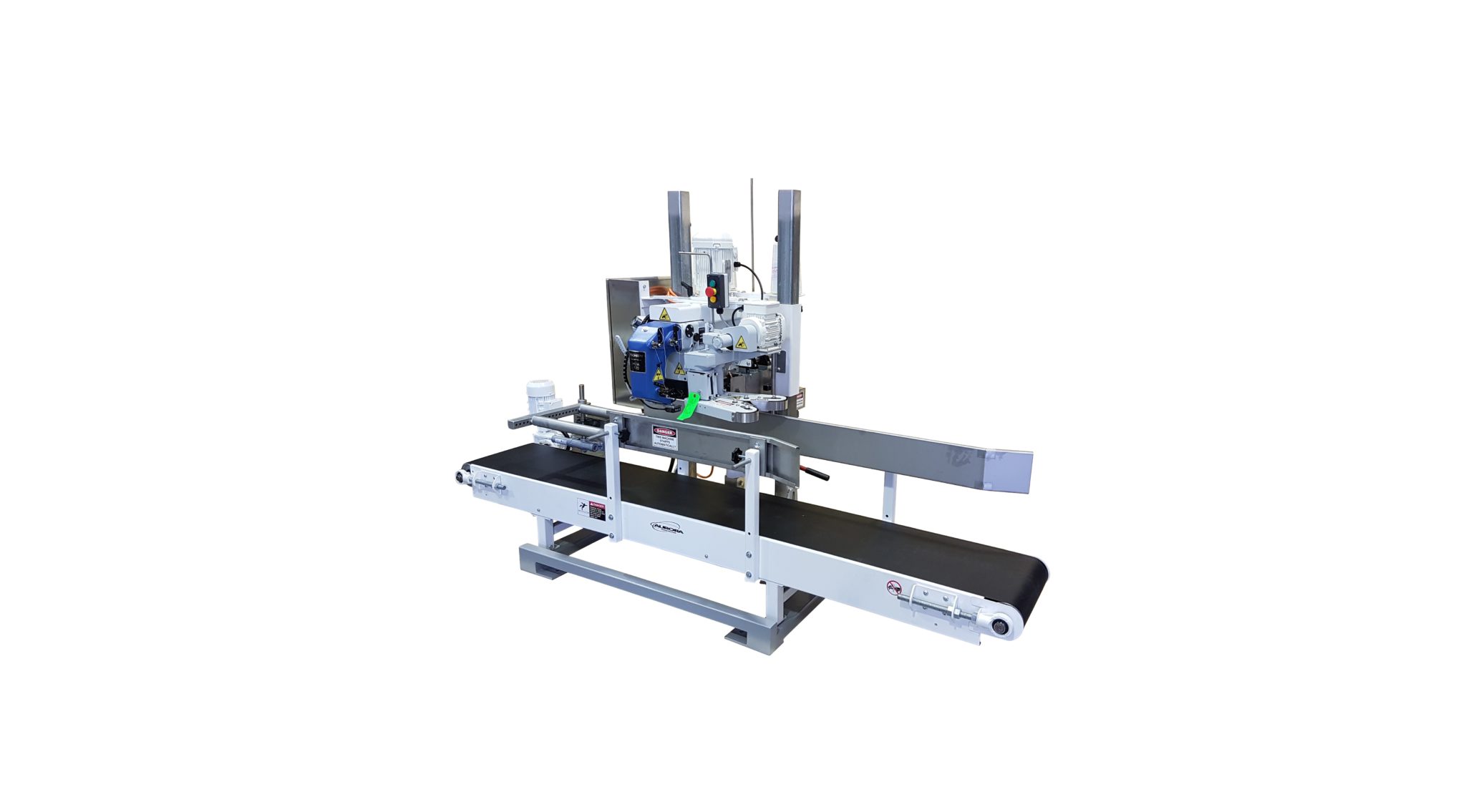

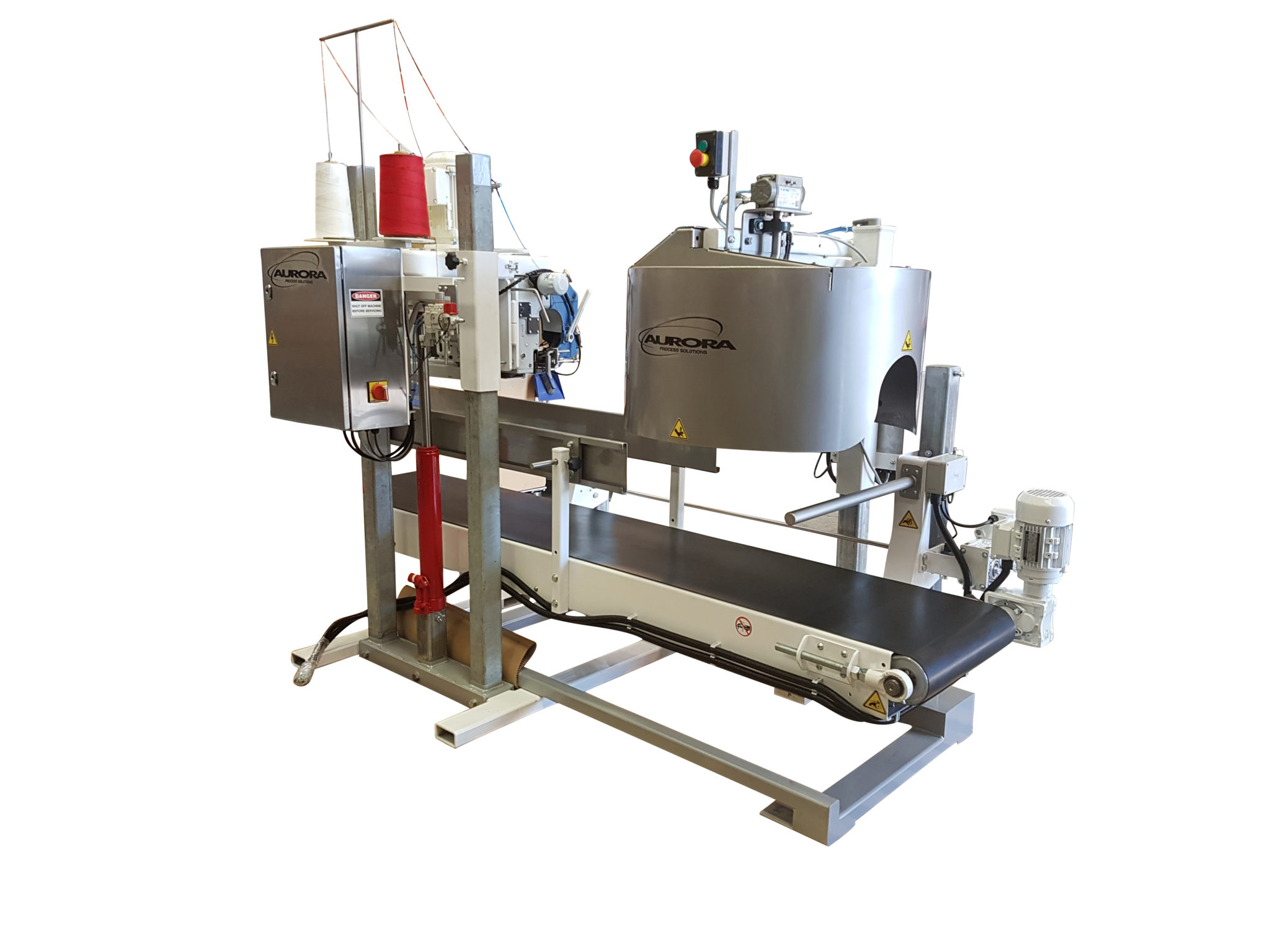

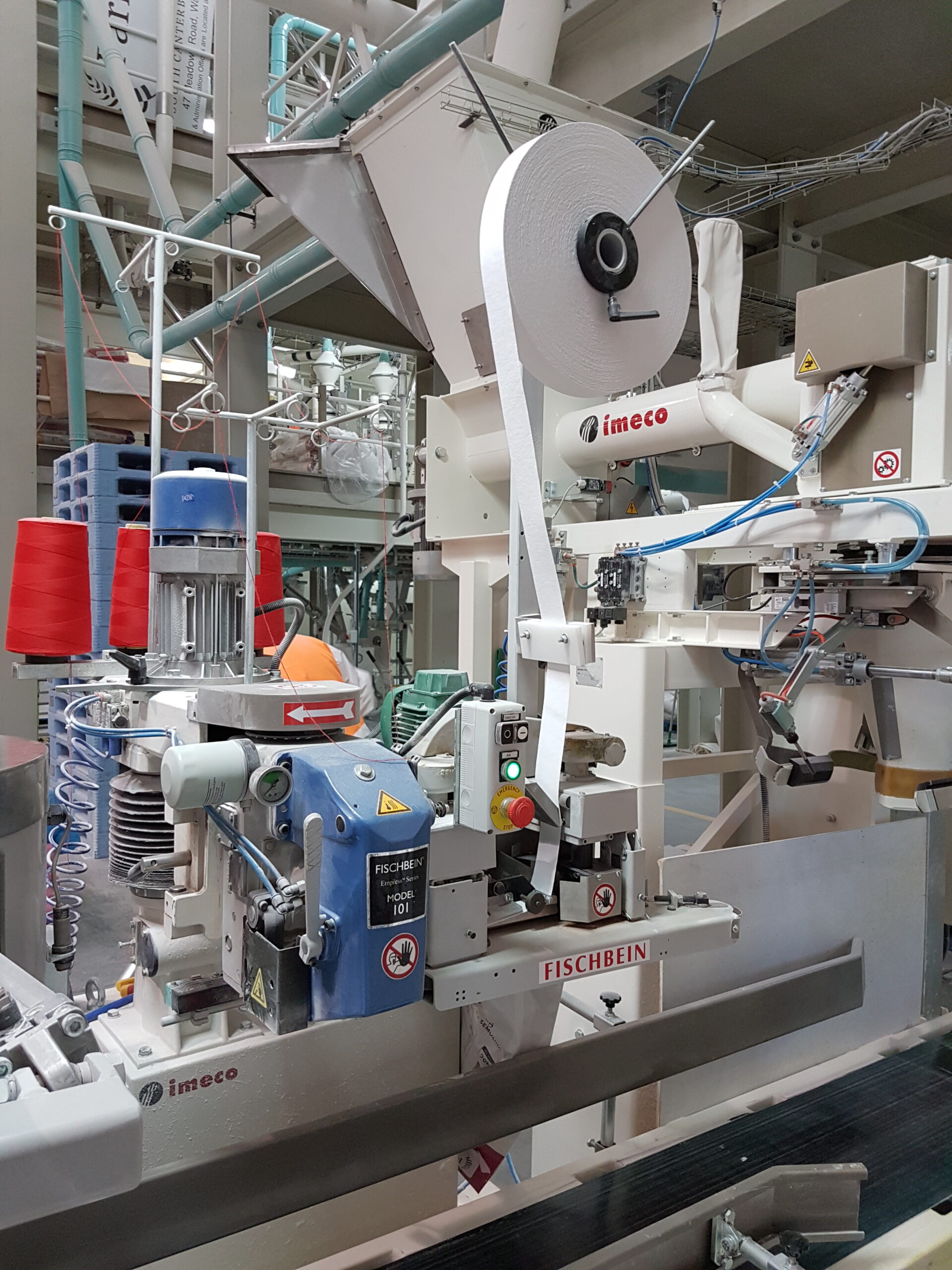

Description

Featuring variable speed and a compact design, Model 100 Standard Sew and Model 101 Tape Sewing Heads are the latest innovations in trouble free bag sewing technology. With an easily adjustable sewing speed from 8—22 m/min, the Industrial Sewing System is perfect for sewing every type of open-mouth bag including paper, woven propylene and jute.